Ukugquma iimpompo

I-1, i-oxidation yomphunga: thepha kubushushu obuphezulu bomphunga wamanzi, umphezulu wokwakheka kwefilimu ye-oxide, i-adsorption epholileyo ilungile, inokudlala indima ekunciphiseni ukungqubana, ngelixa ikhusela impompo kunye nezinto zokusika phakathi kwebhondi, ifanelekile. ukulungiselela intsimbi ethambileyo.

I-2, unyango lwe-nitriding: i-nitriding yempompo yomphezulu, yenza umaleko wokuqina, olungele ukusetyenzwa kwentsimbi, i-aluminium kunye nezinye izinto ezinxitywayo.

3, umphunga + nitriding: iingenelo ezibanzi kwezi zimbini zingasentla.

I-4, i-TiN: i-coat yegolide etyheli, ubulukhuni obuhle bokugquma kunye nokuthambisa, kunye nokusebenza kokuncamathela kulungile, kukulungele ukusetyenzwa kwezixhobo ezininzi.

I-5, i-TiCN: i-blue grey coating, ubunzima malunga ne-3000HV, ukumelana nobushushu be-400 ° C.

I-6, i-TiN + TiCN: i-coat emnyama emnyama, enobulukhuni obunqabileyo bokugquma kunye ne-lubricity, ilungele ukusetyenzwa kwezinto ezininzi.

I-7, i-TiAlN: i-blue grey coating, ubunzima be-3300HV, ukumelana nobushushu ukuya kwi-900 ° C, ingasetyenziselwa ukuqhutyelwa kwesantya esiphezulu.

I-8, i-CrN: isilivere engwevu yokwaleka, ukusebenza kokuthambisa kuphezulu, ikakhulu kusetyenziselwa ukusetyenzwa kweentsimbi ezingenayo i-ferrous.

Ukugquma kompompo kunempembelelo enkulu ekusebenzeni kompompo, kodwa okwangoku, abavelisi kunye nabavelisi beengubo bayasebenzisana kunye ukuze bafunde i-coating ekhethekileyo, njenge-LMT IQ, i-Walther THL, njl.

Izinto ezichaphazela ukucofa

A. Izixhobo zokucofa

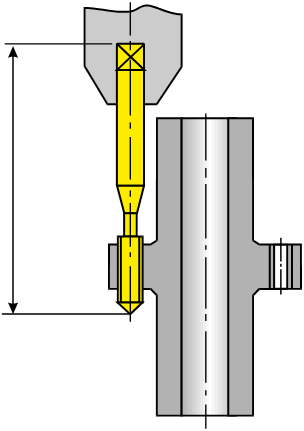

1. Isixhobo somatshini: sinokwahlulwa ngokweendlela ezithe nkqo nezithe tye.Ukucofa, ume nkqo ungcono kunokulungiswa okuthe tye, kwaye ukusetyenzwa okuthe tye kufuneka kuthathelwe ingqalelo ukuba ngaba ukupholisa kwanele.

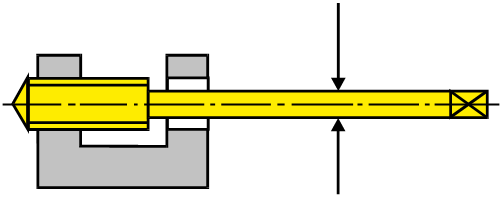

I-2, i-tapping shank: ukucofa kucetyiswa ukuba kusetyenziswe i-shank ekhethekileyo yokucofa, ukuqina komatshini, ukuzinza okulungileyo kukhethwa ukukhetha i-synchronous tapping shank, ngokuchaseneyo, ngokusemandleni ukukhetha i-flexible shank kunye nembuyekezo ye-axial / radial.Sebenzisa i-square drive nanini na kunokwenzeka, ngaphandle kweempompo zedayamitha ezincinci (

3. Iimeko zokupholisa: xa ucofa, ngakumbi iitephu zokukhupha, imfuneko yokupholisa kukuthambisa > ukupholisa;Ekusetyenzisweni kwangempela, kunokulungiswa ngokwemiqathango yesixhobo somatshini (xa usebenzisa i-emulsion, kucetyiswa ukuba ukugxininiswa kukhulu kune-10%).

B. Umsebenzi oza kucutshungulwa

1. Izinto eziphathekayo kunye nobunzima bomsebenzi owenziweyo: ubunzima bezinto zokusebenza kufuneka zibe yinto efanayo.Ngokuqhelekileyo akukhuthazwa ukuba kusetyenziswe iimpompo ukuze kusetyenzwe i-workpiece ngaphezulu kwe-HRC42.

2, ukucofa umngxuma ongezantsi: isakhiwo somngxuma osezantsi, khetha i-bit elungileyo;Ukuchaneka komngxuma ongezantsi;Ubunzima bodonga lomngxuma ongezantsi.

C. Iiparamitha zokucubungula

I-1, isantya: isantya sinikezelwa ngesiseko sohlobo lwempompo, izinto eziphathekayo, izinto ezicwangcisiweyo kunye nobunzima, iingenelo kunye nokungahambi kakuhle kwezixhobo zokucofa.

Ngokuqhelekileyo ikhethwe ngokweeparamitha ezinikwe ngumenzi wempompo, isantya kufuneka sincitshiswe phantsi kwezi meko zilandelayo:

▶ ukuqina kwesixhobo somatshini akubi kakuhle;Ukubetha itephu enkulu;Ukungapholisi ngokwaneleyo;

▶ Isixhobo sendawo yokucofa okanye ubulukhuni abufani, njengamajoyinti e-solder;

▶ Itephu yolulwa, okanye kusetyenziswa intonga yokwandisa;

▶ Igqudu, ingqele ngaphandle;

▶ Ukusebenza ngesandla, okufana ne-bench drill, i-rocker drill, njl.;

2, isondlo: ukucofa okuqinileyo, ukondla =1 pitch/turn.

Ukucofa okuguquguqukayo, kunye nokuguquguquka kwembuyekezo ye-shank kwanele:

Ukutya = (0.95-0.98) pitch/revolution.

Ezinye iingcebiso ekukhetheni itephu

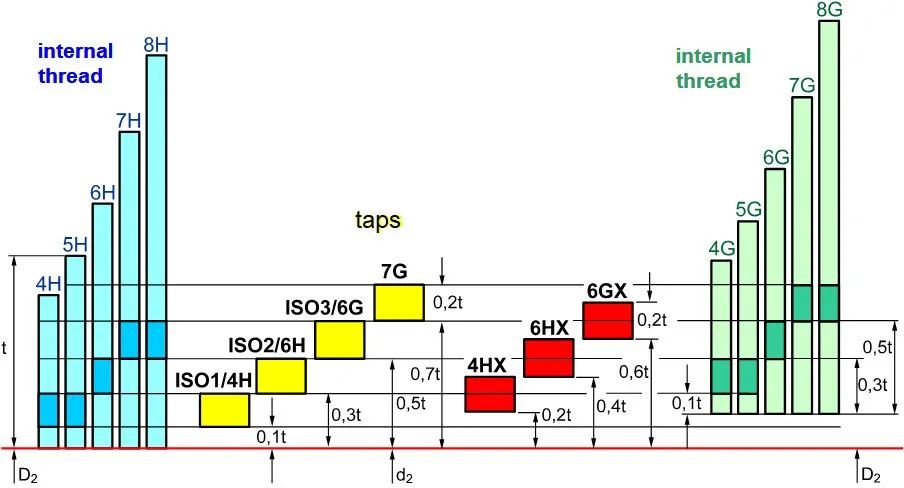

A. Ukunyamezela iimpompo zamabakala ahlukeneyo achanekileyo

Isiseko sokhetho: hayi kuphela ngokwebakala elichanekileyo lomsonto oza kwenziwa ngoomatshini ukukhetha nokumisela ibakala elichanekileyo lompompo

▶ Izinto kunye nobunzima bomsebenzi owenziweyo;

▶ Izixhobo zokucofa (ezifana neemeko zomatshini, umqheba wokubamba, iringi yokupholisa, njl.);

▶ Itephu ngokwayo ichanekile kunye nempazamo yokwenziwa kwayo.

Umzekelo: ukucutshungulwa kwentambo ye-6H, kwiprosesa yensimbi, unokukhetha i-tap ye-6H echanekileyo;Kwinkqubo yentsimbi yentsimbi engwevu, ngenxa yokuba i-diameter ephakathi yempompo inxiba ngokukhawuleza, ukwandiswa kwe-screw hole kuncinci, ngoko kuyafaneleka ukukhetha itephu echanekileyo ye-6HX, ubomi buya kuba ngcono.

Inqaku malunga nokuchaneka kweempompo zaseJapan:

▶ Ukusika impompo ye-OSG isebenzisa inkqubo ye-OH echanekileyo.Ihluke kwi-ISO ye-ISO, i-OH yokuchaneka kwenkqubo inyanzelisa yonke ububanzi bebhendi yokunyamezela ukusuka kumda ophantsi, yonke i-0.02mm njengenqanaba elichanekileyo, elibizwa ngokuba yi-OH1, OH2, OH3, njl.

▶ Impompo ye-Extrusion ye-OSG isebenzisa inkqubo yokuchaneka kwe-RH, inkqubo yokuchaneka kwe-RH iya kunyanzela ububanzi bokunyamezela bonke ukusuka kumda ophantsi, yonke i-0.0127mm njengenqanaba elichanekileyo, elibizwa ngokuba yi-RH1, RH2, RH3 njalo njalo.

Ke ngoko, xa utshintsha impompo ye-OH echanekileyo ngempompo yokuchaneka kwe-ISO, i-6H ayifanele ithathwe njengelingana nenqanaba le-OH3 okanye i-OH4.Kufuneka kugqitywe ngokuguqulwa okanye ngokwemeko yangempela yomthengi.

B. Imilinganiselo yangaphandle yempompo

1. Okwangoku, ezona zisetyenziswa kakhulu yi-DIN, ANSI, ISO, JIS, njl.

2, ngokweemfuno zomxhasi ezahlukeneyo zokucwangcisa okanye iimeko ezikhoyo ukukhetha ubude obufanelekileyo, ubude beblade kunye nokusingatha ubukhulu besikweri

3. Ukuphazamiseka ngexesha lokucubungula;

Cofa ukhetho lwezinto ezintandathu ezisisiseko

I-1, uhlobo lwentambo yokucubungula, i-metric, iBritish, iMelika, njl.;

2. Uhlobo lomngxuma ongezantsi womsonto, ngomngxuma okanye umngxuma oyimfama;

I-3, i-workpiece esetyenzisiweyo kunye nobunzima;

I-4, i-workpiece igcwele ubunzulu bomsonto kunye nobunzulu bomngxuma ongezantsi;

I-5, intambo yokusebenzela echanekileyo;

I-6, ukubonakala komgangatho wempompo (iimfuno ezikhethekileyo kufuneka ziphawulwe).

Ixesha lokuposa: Sep-22-2022